Contact Details

Address: 157, Road 5, Minden Heights, 11700 Gelugor, Penang, Malaysia Email ID: enquiry@cejipac.com

Specification

CONTAINER DESICCANT ACTIVATED CLAY DESICCANT

DESCRIPTION

Combination of a small amount of Calcium Chloride with a natural clay that gives high absorptive properties.

TYPICAL APPLICATION

Dehumidifying agent for containers and for general applications.

TYPICAL CHEMICAL ANALYSIS

Attapulgite Clay and Calcium Chloride

SiO2 |

64.21% |

Al2O3 |

9.04% |

Fe2O3 |

4.15% |

MnO |

0.87% |

TiO2 |

0.55% |

CaO |

1.80% |

MgO |

4.56% |

K²O |

0.75% |

Na²O |

0.07% |

CaCl² |

14.00% |

Physical Properties |

|

Moisture |

≤3% |

Colour |

Grey |

Moisture Absorption |

≥45% Dry Weight |

CaCl2 |

|

Specification |

|

CaCl2 |

min 96% |

Na |

max 1.2% |

K |

max 0.12% |

Mg |

max 0.06% |

SO4 |

max 0.05% |

Alkalinity as Ca(OH)2 |

max 0.15% |

Insoluble in water |

max 0.20% |

PH in 10% CaCl2 |

|

Solution at 20 C |

9 – 10.5 |

PACKAGING

The 2-kg, 1-kg and 500-gm bags are packed in nonwoven fabric , woven fabric or a combination of these fabrics. The 1-kg and 2-kg bags are fitted with plastic hooks or shoe strings for them to be hung from the container hooks.

STORAGE AND HANDLING

The desiccant is highly hygroscopic and will activate instantly with free moisture. For this reason, the desiccant is packed and shipped in airtight packaging materials. To ensure the best possible desiccant performance, follow these simple rules:

1.Check desiccant packaging on delivery. In the event of damage to the outer packaging material the desiccants are most probably exposed to the atmosphere and therefore the product is exposed . Do not accept the goods.

2.Open the protective plastic bag only when ready to use the desiccant. After use, if some desiccants are still left over in an opened bag, securely close the bag to ensure that no free moisture can be absorbed by the desiccants. Or put the unused desiccants in an air-tight container.

3.If, for some reason, the protective plastic bag has been left open for a period of time , weight some of the desiccants to establish if their weight have increased. If there is a weight increase of more than 15%, it is strongly recommended not to use the desiccant.

4.Store in a cool dry place

5.The product in its original unopened packing has a shelf life of at least one year if stored in a dry place at 25 deg.C and RH <= 60%.

Application

APPLICATIONS – CONTAINER DESICCANTS

General

Container desiccants are used to adsorb the excess moisture in the surrounding air inside a closed container thus preventing condensation from taking place when the atmospheric temperature drops .The temperature drop may occur due to change in weather , at night or when the vessel moves to a different climatic zone.

The condensation will take place as cargo sweat or container rain.

1) How to use it?

Articles

Training

Introduction

What is a desiccant?

Any substance that can absorb/adsorb moisture from the air

Purpose

Prevention of:

Mould

Odour

Rust

Why Desiccant?

Mould

20 deg C

50 – 60 % relative humidity (RH)

Rust

At and above 45% RH

Condensation

Example

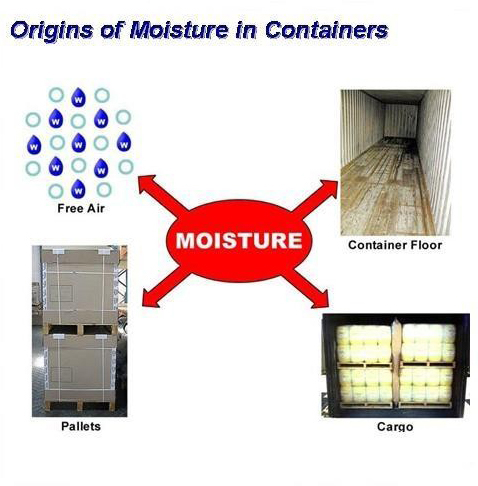

Moisture in Containers

Heating & Cooling

Moisture In The Air

Moisture In Wood

Use a moisture meter

Example:

Moisture Reading = 15%

Weight of pallet = 20kg

Moisture content = 0.15 x 20 kg=3kg

Adsorption Capacity

Amount of water vapor adsorbed by a desiccant at a given temperature and RH

AC = Final weight – Initial Weight x100% Initial weight

Desiccant Unit Weight

Under MIL-D-3464, a desiccant unit is the quantity that will at 25 deg C adsorb the following quantities of water vapor:

(a) 3.00 gms at 20% RH and

(b) 6.00 gms at 40% RH

Factors Affecting Condensation

1. Maximum temperature

2. Minimum temperature

3. Shipping duration

4. Moisture content inside the container

Quick Estimation Of Desiccant Required

1. Add the total quantities of water vapor available from all sources

2. Quantity of desiccant required: Qty = Total qty of water vapor x1/3 x100 Adsorption capacity in %

Using Software

Follow MIL-STD-2073

A. Formula I – To find units of desiccant for use within a sealed non-metallic container :

U = CA + X1D + X2D +X3D +X4D

B. Formula II – To find units of desiccant for use within a sealed rigid metal container:

U = KV + X1D +X2D + X3D + X4 D ,where

U = The number of units of desiccant to be used

C =0.001,K =0.0007,X1=8.0 for cellulosic matl

A = Area of container(barrier) in sq. in.

V = volume of rigid container in cubic in.

X2 =3.6 for bound fibers,X3 =2.0for glassfibers

X4 = 0.5 for synthetic foam & rubber

D = pounds of dunnage within container

Packaging Material

1. Paper

2. Paper with plastic or synthetic material

3. Tyvek ( spunbonded PP )

4. Woven Material

5. Fabric (Non-woven)

How To Use?

1. Place in void of item or pack interior

2. Not covered or blocked

3. Properly secured

4. Evenly spaced

5. Not in direct contact with enclosed item

6. For containers, put in highest position and seal ventilation holes

7. Last action before sealing of container

Protecpac Desiccant

| MD | MT | |

| Adsorption Cap. | 50% | 20% |

| Sizes, gm | 0.5-2k | 0.5-2k |

| Packaging matl | Complex | Paper |

| Tyvek | Tyvek | |

| Fabric | Fabric | |

| Recommended Use | Containers | Food, Medicine |

| General | Electronic goods |

DESICCANT

What is a desiccant and how does it works?

A desiccant is any substance that can adsorb moisture from the surrounding air .As a result of pores in the desiccant material , it can also hold a significant amount of water,A sponge is not a desiccant even though it can hold a lot of water . Examples of common desiccants are :

1) Silica gel

This is the most common desiccant which can be found in bottles of medical or vitamin capsules/tablets.

It is actually a chemically produced non corrosive form of silicon dioxide and comes in grains or beads.. The many interconnected pores in the grains adsorb moisture from the air and hold them by capillary action.

As it is relatively more expensive , silica gel normally comes in small satchets ranging from 1gm to 50gm and placed with the products to keep them dry.

2) Clay desiccant

Some types of clay like montmorillonite and bentonite behave like a dessicant as the minute pores between the grains adsorb moisture from the air. The clay also has the ability to hold a significant amount of water.

The clay is packed in nonwoven bags in 500gm, 1-kg or 2-kg packings as clay is much cheaper than other desiccant types. A small amount of the hygroscopic salt, calcium chloride, may be added to the clay( called activated clay or mineral desiccant) to improve its adsorption capacity.

3) Molecular sieve

This is a synthetic desiccant manufactured as crystalline hydrated aluminosilicates .The small pore sizes of the cystalline particles will adsorb moisture from the air . It is relatively most expensive and normally packed in a cylinder for in-line drying of gases.

4) Calcium Chloride

This is a hygroscopic salt which can absorb up to ten times its weight of moisture under the right conditions. It is normally placed in a plastic container to hold the big amount of resulting salt solution. The salt solution can cause corrosion when it comes in contact with the product or container.

The latest development include the addition of gel to the clacium chloride so that the salt solution is held by the gel( very much like the baby diaper). This enable the calcium chloride & gel desiccant to be packed in nonwoven bags for cheaper packaging and easy use inside the container.

DESICCANT PERFORMANCE

We can leave a 1-kg bag of container desiccant in the open in our office after taking down its weight. Continue to weigh the bag of desiccant every day at about the same time and record its weight till there is no more change in weight for 3 consecutive days. Plot the weight gain percentage ( weight gain divided by the initial desiccant weight ,expressed in percent) against the number of days on a graph.It will typically look like the graph below.

The weight gain percentage will rise rapidly for a few days and then starts to reach a plateau after many days. The gradient is a measure of how fast the desiccant is adsorping moisture from the surrounding air and is called the rate of adsorption .The plateau indicates that the desiccant has reached its saturation point and it is called the adsorption capacity of the desiccant .This measures the maximum adsorption capacity of the desiccant.

The adsorption rate and adsorption capacity changes with the relative humidity (RH) and ambient temperature .Therefore in the specification sheet for the desiccant the manufacturer will indicate the RH and ambient temperature for their data. For practical purposes, we can use this method to evaluate any desiccant which we intend to use .

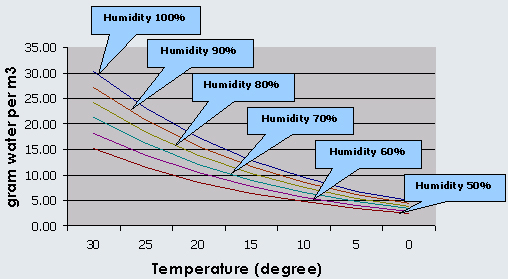

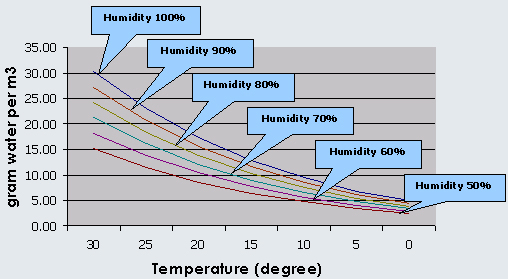

MOISTURE IN THE AIR ( GM WATER PER M3 VS TEMP IN DEG C AT VARIOUS HUMIDITY LEVEL)

| 30 | 25 | 20 | 15 | 10 | 5 | 0 | ||

| Humidity | 100% | 30.32 | 23.01 | 17.27 | 12.82 | 9.39 | 6.79 | 4.84 |

| 90% | 27.29 | 20.71 | 15.54 | 11.54 | 8.45 | 6.11 | 4.36 | |

| 70% | 21.22 | 16.11 | 12.09 | 8.97 | 6.57 | 4.75 | 3.39 | |

| 50% | 15.16 | 11.51 | 8.64 | 6.41 | 4.7 | 3.4 | 2.42 |

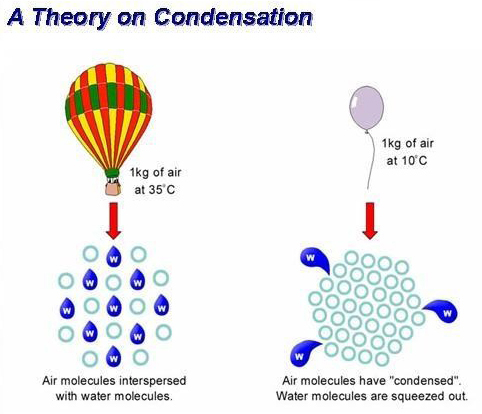

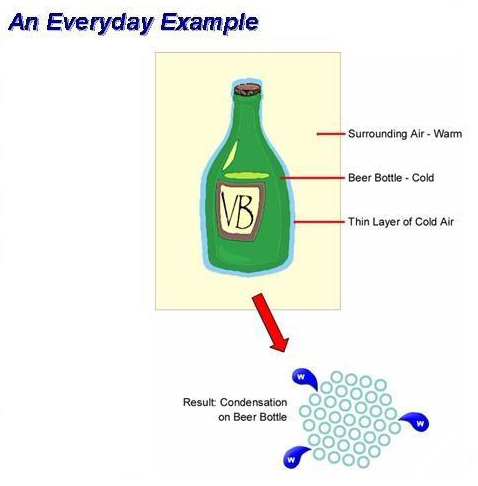

CONDENSATION

Why does water condensation take place inside a closed container?

Moisture in the form of water vapour is ever present in the surrounding air. The amount of moisture that the air can hold is directly proportional to the temperature. When the ambient temperature is higher during day, the surrounding air will draw up moisture( a process called evaporation) from any source with water content, for example, the container floor ( which is wooden), wooden pallets, wooden crates or from the cargo if it contains moisture. However, when the anbient temperature drops (example, at night) the surrounding air cannot hold the excess mositure(as the relative humidity,RH, cannot exceed 100%) which will then condense onto the roof the container . This condensation will then fall down onto the cargo – a process called container rain.This drop in temperature happens daily according to the time of the day or due to changes in the weather conditions(eg. from sunny to raining) .When the vessel moves to a different climatic zone( eg, from tropic to a temperate zone), the changes in anbient temperature also takes place. This evaporation and condensation cycle takes place continually, following the changes in the ambient temperature.

METHOD FOR QUICK ESTIMATION OF DESICCANT REQUIRED FOR CONTAINERS

Sources of moisture

• Free air volume inside the container

• Moisture from cargo (if any)

• Moisture from wooden pallets (if any)

• Moisture from wooden container floor

Moisture content of the free air volume inside the container(MA)

Volumetric capacity of containers :

• 2.1.1 20 –footer - 33m3

• 2.1.2 40-footer - 67m3

Estimate % free space left after all the cargo has been loaded into the container eg. 10%

Volume of free space in container

Vol . of free air space = % free space x cubic capacity of container

Example: Vol. of free air space = 10% x 33 m3 = 3.3m3

Moisture content in air ( Available from psychometric charts) Take as 27gm/m3 of moisture in air at 30degC and 90% RH.

Moisture content of free air inside container

Moisture content of air (MA) = Vol. of air space in m3 x 27 gm

Example: MA = 3.3 x 27 = 89.1gm

Moisture content from cargo (MC)

Look at the type of cargo and work out the amount of moisture from the product data sheet or get from the product manufacturer.

Moisture content from wooden pallets (MP)

• Measure the moisture content % using a moisture meter.

• Weigh the pallet

• Moisture content of one pallet = % moisture content x weight of pallet ÷ 100

• Total moisture from pallets = (4.3) x total no. of pallets Example:

Moisture reading = 15%

Weight of pallet = 30 kg

Moisture content/pallet = 0.15 x 30 = 4.5 kg

If 10 pallets, total moisture content of pallets(MP) = 10x 4.5 = 45 kg

Estimating the Amount of Desiccant Required(DR)

Find out the adsorption capacity of the desiccant used. This is normally given as % of its dry weight in the data sheet . It tells us how much of moisture will be adsorped by the desiccant as a percentage of its dry weight. Eg. An AC of 50% means 1-kg of desiccant will adsorp ½ kg of moisture at saturation.

Add the amount of moisture from all available sources : MA = Moisture content of free air space in the container

MP = Moisture content of all the wooden pallets / crates

MC = Moisture content of the cargo

MF = Moisture content of the container floor

Amount of desiccant needed(DR) :

DR = (MA + MP + MC +MF) x 1/4 ÷ AC(in %) x 100 OR

DR = 8kg ( for 20-footer), whichever is more OR

DR = 16kg ( for 40-footer) , whichever is more

The minimum amount of desiccant required is 8 kg for 20-footer or 16 kg for 40-footer.

Example:

No moisture from cargo , Adsoption capacity of desiccant =50%, shipment to Japan in summer DR = (0.089 +45 + 9.0) x 1/5÷50 x 100=21.6 kg

Precautions

• Ensure that the container floor is dry before loading in the cargo.Otherwise, exchange for one with a dry floor or open the doors and let it air dry.

• Cover all the air ventilating holes in the container with masking tape. These are normally found at the top of the container walls – one set at the rear end and the other set at the door end.

• It would be a great help to line the container floor with plastic sheet before loading in the cargo. This will reduce the amount of moisture that will be released by the container floor. Any PP or PE sheet ( new or old, thick or thin ) can be used.

• It is recommended to increase amount of desiccant used by 10- 15% during the winter months at the receiving destination. This is because the low temperatures will lower the condensation point drastically.

RECOMMENDED AMOUNT OF ACTIVE MINERAL DESICCANT IN CONTAINERS

K=0.4( 0.028V+3P + 0.12P)

where: K=Amount of desiccant required in kg.

• V=Volume of free air space inside the container after loading in m³

• P=No. of wooden pallets used

• F= 280 for 20-footer and 560 for 40-footer GP container

| Amount of desiccant in kg | ||||

| Condition | 20-footer | 40-footer | ||

| Without wooden pallets | 8kg | 16kg | ||

| With 10 pcs wooden pallets | 25 | - | ||

| With 20pcs wooden pallets | 37 | 51 | ||

| With 40 wooden pallets | - | 75 | ||

Notes:

• The default amount for a 20-footer is 8kg and 16kg for a 40-footer.

• It is assumed that the goods and its packaging does not contain water .

• It is assumed that the free air space inside the container after loading is 10%.

• It is assumed that the average weight of a wooden pallet is 20kg and mositure content is 12 %.

• It is assumed that the average moisture content of the container floor is 12%.

• It is assumed that the adsorption capacity at 37°C, 90%RH is 50%