Contact Details

Address: 157, Road 5, Minden Heights, 11700 Gelugor, Penang, Malaysia Email ID: enquiry@cejipac.com

Specification

1. DESCRIPTION

Woven polyester strapping of specified width

2. REFERENCE

2.1 ASTM D3950-05 , Standard Specification for Strapping , Nonmetallic(and Joining Methods)

3. MATERIAL AND CONSTRUCTION

Longitudinal polyester cords woven with a weft thread to form a woven material.

4. COLOUR & MARKING

Standard :Natural ( white)

Optional : Any color coating

Optional : Single color logo marking one metre apart on strapping

5. SPECIFICATION

5.1 Breaking strength: as specified

5.2 Nominal width : specified width plus 0.79mm(1/32”) minus 2.37mm( 3/32”)

5.3 Workmanship, Finish, and Appearance

5.3.1 The strapping shall be straight, clean, have good webbing , and be free of cracks and other defects that may affect the serviceability

5.3.2 Splices may be made if they do not affect the serviceability of the strapping in strapping equipment and have a break strength equal to at least 50% of the strap break strength . No more than one splice per coil will be permitted.

6. CORE SIZE( BOBBIN SIZE)

6.1ID : 95mm( 3 3/4”) nominal or as specified

6.2Height: 140mm( 5 1/2”) nominal or as specified

6.2Material : Cardboard of thickness 6 mm nominal or as specified

6.3No core for lashings above 32mm width and breaking strength1500kgf

7. COIL STATISTIC

7.1 Length/coil: as specified

7.2 External Diameter of coil: as specified

7.3 Weight / coil : as specified

8. PACKING BOX

8.1 coils/carton box: as specified

8.2 Gross Weight /carton: as specified

8.3 Color of carton is white/brown and requires stapling at joints to prevent tearing

8.4Double walled corrugated card board material

8.5 Markings

As per specification or per the following format:

WOVEN POLYESTER CORD STRAPPING

WIDTH:

B. S. :

COIL LENGTH:

NO. OF COILS/BOX:

9. PALLET PACKING

9.1 Carton boxes layout: as specified

9.2 No. of boxes /pallet: as specified

9.5 Gross weight /pallet:as specified

Gross weight of a palletized load shall not exceed 1100kg(2420 lbs)

| REVISION HISTORY | |||||

| DATE | REV | CHANGE | WHOM | ||

| 11/11/2010 | A | Original Issue | NM Chew | ||

| 1/01/2011 | b | Change | NM Chew | ||

WOVEN POYESTER CORD STRAPPING

| Light Duty | |||||

| Width mm/inch 13mm / 1/2" 16mm/ 5/8" 19mm / 3/4" |

Breaking Strength kgf / lbs 310kgf / 680lb 360 kgf . 792 lb 430 kgf / 950 lb |

Length/Coil m / ft 1190m / 3900' 915m /3000' 640m / 2100' |

Coil Size inches 3"x51/2"x12" 3"x51/2"x12" 3"x51/2"x12" |

Coils/box 2 2 2 |

|

| Medium Duty | |||||

| 13mm / 1/2" 16mm / 5/8" 16mm / 5/8" 19mm / 3/4" |

383kgf / 843lb 460kgf / 1011lb 613kgf / 1348 lbs 660kgf / 1450lb |

1100 m / 3609' 850m / 2789' 600m / 1969' 760m / 2500' |

3"x51/2"x12" 3"x51/2"x12" 3'x51/2"x12" 3"x51/2"x13" |

2 2 2 |

|

| Heavy Duty | |||||

| 19mm / 3/4" 19mm / 3/4" 25mm / 1" 25mm / 1" 32mm / 11/4" |

767kgf / 1686lb 1124kgf /2472lb 613kgf / 1348lb 1222kgf / 2688lb 1500 kgf / 3300lb |

500 m/ 1640' 400m /1312' 500 m/ 1640' 500m / 1640' 300m / 1080' |

3"x51/2"x12" 3" x 51/2"x12" 3" x 51/2"x12" 3"x51/2"x12" 31/2"x51/2"x15" |

2 2 2 2 2 |

|

| WOVEN POLYESTER CORD LASHING | |||||

| 32mm / 11/4" 38mm/11/2" 40mm / 15/8" 50mm / 2" 50mm / 2" |

2350 kgf / 5170lb 3576 kgf / 7868lb 5109kgf / 11240lb 5109kgf / 11240lb 7664 kgf / 16860lb |

250m / 820' 200m / 656' 200m/656' 200 m/ 656' 150m / 492' |

2 2 1 1 1 |

||

Notes:

1. The strappings are wound onto cardboard cores of internal diameter 76mm, 90mm or n95mm, thickness 10-15mm

2. The lashings are wound in coils without any cardboard cores

3. Markings are normally in black to indicate product code and breaking strength , if required by manufacturer

4. Color is normally natural unless specified by customer for OEM.

| Woven Polyester Cord Strappings & Lashings | |||||

| Description | Width (cm) | Linear Breaking | Coil Length (m) | Jointing Method | Packaging |

| Strength (kgf) | |||||

| 13mm Strapping | 13 | 383 | 1100 | Knot, wire buckle | 2 coils/box |

| 16mm Strapping | 16 | 460 | 850 | Knot,wire buckle | 2 coils/box |

| 19mm Strapping | 19 | 660 | 600 | Knot,wire buckle | 2 coils/box |

| 25mm Strapping | 25 | 1200 | 500 | Knot,wire buckle | 2 coils/box |

| 32mm Strapping | 32 | 1500 | 300 | Knot,Wire buckle | 2 coils/box |

| 38mm Lashing | 38 | 3500 | 200 | welded ,cam or ratchet buckle | 2 coils/box |

| 40mm Strapping | 40 | 5000 | 200 | Welded ,cam or ratchet buckle | 2 coils/box |

| 50mm Strapping | 50 | 7500 | 150 | Welded , cam or ratchet buckle | 2 coils/box |

Properties of Polyester Strappings & Lashings

1. Very high strength -as strong as steel

2. Safe for users and receivers

3. Light weight and easily portable

4. Will not rust or rot

5. Weather resistant

6. Shock absorbent

7. Prevents damage to products

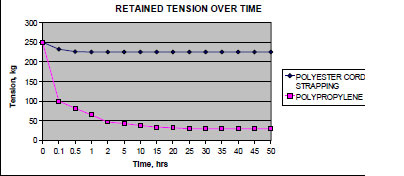

8. High retained tension

9. Can be used with manual knotting, wire buckles , welded buckles or cam buckles

Types of buckles

Applications – Woven Polyester Strappings & Lashings

General

Woven polyester strappings and lashings are normally used to unitize cargo loads on pallets or slip sheets and also to tie down unitized cargo loads in containers and trucks . The strappings from 9mm width to 32mm width are used for unitizing cargo loads while those 32mm and above are used to tie down cargo loads.

Bundling steel pipes /beams /bars

Bundling steel pipes /beams /bars

Bundling steel pipes /beams /bars

Bundling steel pipes /beams /bars

Bundling 25-kg bags

Bundling carton boxes

Bundling Wire Products

Bundling wooden products

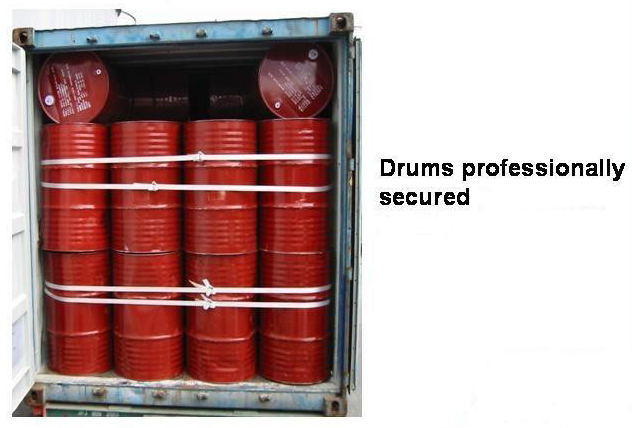

Bundling drums/tins

Bundling drums/tins

Tying down drums in containers

Tying down equipment /machinery in containers

Tying down big bags in containers

Tying down cargo loads in flatracks

Tying down cargo loads in flatracks

Tying down cargo loads in flatracks

Tying down cargo loads in flatracks

Tying down cargo loads in flatracks

Articles

USING POLYESTER CORD STRAPPING FOR CARGO LOAD SECURING

WHAT IS A POLYESTER CORD STRAPPING?

Two types:

Uniline - made up of corded polyester yarns held together in a flat strap by PE or glue

Woven - woven from high tenacity polyester yarn

WHAT IS IT USED FOR?

To bundle or unitised all kinds of load

To secure loads for all methods of transport : by road, rail, sea or air

ADVANTAGES OF POLYESTER CORD STRAPPING

Cost effective

Safe, light and easy to use

Little or no waste

Tension can be adjusted anytime

Creep Resistant

High system strength

Rot-proof

PROPERTIES

High tensile and system strength: 1460 kg linear & 2480 kg system strength

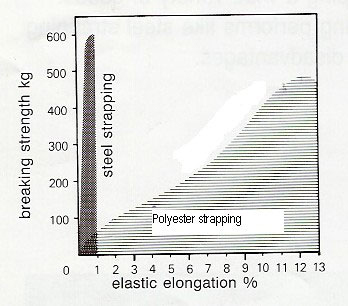

Elastic elongation of 6 - 8%

Shock absorption of 30 – 50 times more than steel strapping

Corrosion resistant

Chemical resistant

UV treated

Temperature resistant : -40 degC to 100 deg C

Buckle closure system

Light weight, soft texture

Easy disposal

SHOCK ABSORPTION

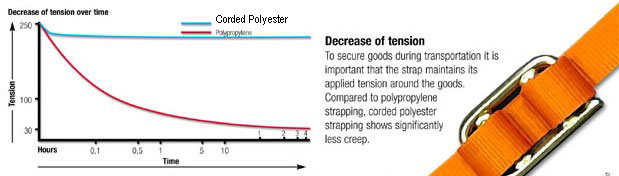

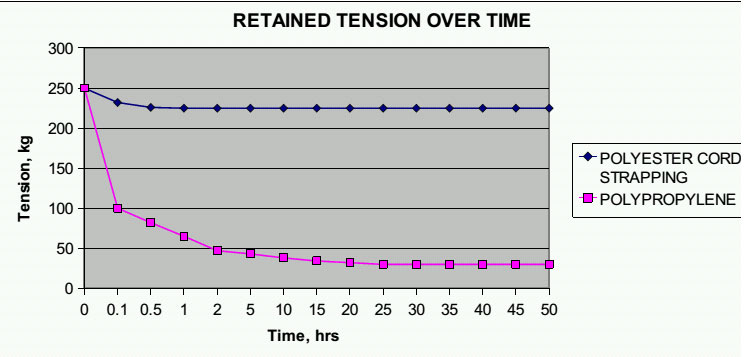

WHAT IS CREEP?

It is defined as the decrease in tension over time.

SYSTEM STRENGTH

Linear strength or breaking strength(BS) is determined by tensioning both ends of a strap until it breaks.

System strength(SS) is measured with the strapping in closed loop joined with a buckle

SS = BS x 2 x Joint Efficiency

Example for the 31XTR

SS = 1460 x 2 x 0.85 kg = 2482 kg

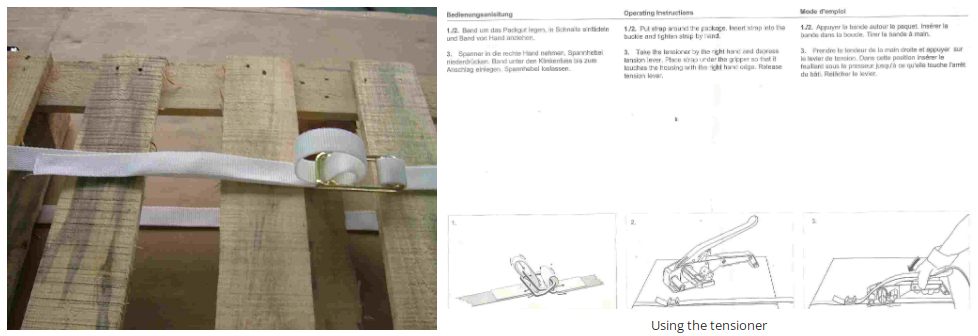

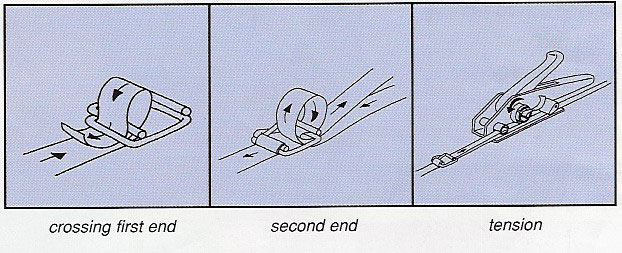

APPLYING THE BUCKLE

Place flat side of buckle against wall or cargo

The prongs of the buckle face right or down

Tension till the prongs close

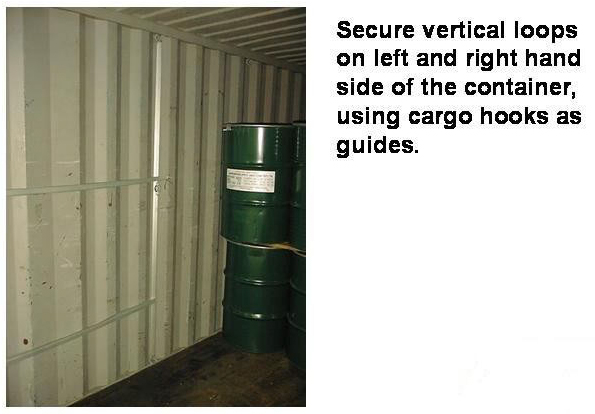

THE HARNESS SYSTEM

An approved system for securing cargo in closed container

Specially useful for 210L drums and bulk bags

Easy to set up

Can also be used together with other cargo securing devices like dunnage bags etc.

STEP 1 – VERTICAL LOOPS

STEP 2 – HORIZONTAL LOOPS

STEP 3 – JOIN HORIZONTAL LOOPS

STEP 4 – TENSIONING

STEP 5 – JOB WELL-DONE

TYPICAL SPECS FOR STANDARD RANGE

| Width(mm) | BS(kg) | Length/coil(m) |

| 13 | 360 | 1100 |

| 16 | 480 | 850 |

| 19 | 580 | 650 |

| 25 | 950 | 500 |

| 32 | 1350 | 150 |

| 38 | 2000 | 100 |

WOVEN POLYESTER CORD STRAPPINGS AND LASHINGS

1)BACKGROUND

The first US commercial polyester fiber production was by Dupont Company in 1953. At that time, the polyester fibers were primarily used for fabric production. There was a growing movement to develop plastic strappings to replace the steel strappings that were widely used then.

Some time later in the 1950’s, the glue bonded polyester cord strapping was developed. At the early stage, these cord strappings were used for simple bundling of goods. The woven strapping was also developed at about the same time frame. In the 1960’s, the composite strapping was developed. By the 1990’s, cord strappings have made major technical advances to largely replace steel strappings in most applications.

2)TYPES OF CORD STRAPPINGS

There are 3 main types of polyester cord strappings depending on their manufacturing processes:

2.1 GLUE-BONDED CORD STRAPPINGS

The linear polyester yarns are held in band by hot-melt glue. This strapping has a soft and tacky feel. Comes only in natural color.

2.2 WOVEN CORD STRAPPINGS

These are woven from high tenacity polyester yarns and can come in any colour. The woven strapping is soft, lightweight and flexible.

2.3 COMPOSITE CORD STRAPPINGS

The linear polyester yarns are co-extruded with polyethylene to produce a stiff strapping band. Only comes in natural colour.

The 3 types of cord strappings are interchangeable in usage. It is just a marketing strategy by manufacturers to diffentiate themselves in order to compete better. Individual customer may have a preference for a particular type based on his individual opinion or usage experience.

3) PROPERTIES

All types of polyester cord strappings and lashings share the same properties:

3.1 Safe

It has no sharp edges and does not spring back when cut under tension.

3.2 Strength

It is really strong as steel!

3.3 No damage to products

As it is soft and flexible, it does not damage the product being bundled.

3.4 Rot-proof

It does not rot or stain.

3.5 Lightweight

It is at least 5 times lighter than the corresponding steel strapping.

3.6 Absorbs Shock Better

With about 10% elastic elongation, it can absorb shocks very well.

3.7 High system Strength

When used with a steel wire buckle it provide high system strength and can be retensioned at any time.

3.8 Creep Resistance

Once tensioned it retains its tension.

4) PERFORMANCE

4.1 Linear Break Strength (Tensile Strength) The most common measure used is the linear break strength where a length of the strapping is pulled till failure. This is following the ASTM standard.

4.2 System Strength The Europeans decided that the system strength is a better measure as it tests the whole loop including the buckle which is how the strapping is used. The system strength shall be double the linear break strength if the buckle is 100% efficient.

4.3 Energy To Break The latest trend is that the energy to break is the most complete measure of strength. This measures the energy required to break the strapping. It is the area under the curve in the force-elongation graph.

4.4 Joint Strength In all applications, strappings have to be joined together into a loop. The joint is also the weakest link in the loop. The common jointing methods are heat seal, crimps, seals and buckles. For the polyester cord strappings , buckles are the only means of forming strong joints. There are two main types of buckles being used for cord strappings and lashings:

i)Wire buckles are used for strappings up to 32mm width.

ii)Welded rectangular buckles are used for lashings of width 32mm and above. Buckles with hooks or cam buckles may also be usedwhen lashings are used to tie down cargo loads for transportation.

The joint strength is normally called the buckle efficiency which is the measured system strength divided by twice the linear break strength and given in percentage. Buckle Efficiency= (Measured system strength / 2 x Linear break strength) x 100%. The buckle efficiency normally range from 75%- 95%, depending on how well the buckle is designed and produced.

4.5 Creep Strappings are expected to maintain its applied tension around the goods over time. Unfortunately, it is a natural phenemenon for tensioned strapping systems to lose strength over time and this is called creep . It has been shown that the corded polyester strapping with wire buckle system has less than 10% creep and is far superior to other strapping and jointing systems.

4.6 Shock Absorbency The polyester strappings have an elastic elongation of about 8-12 %. During the elastic elongation phase , the tensioned strapping will return to its original state once the tension is released. In application, this acts as a shock absorber to absorb sudden load and return to the normal state once the shock is over.

5) ACCESSORIES

5.1 Tensioners A tensioner (either manual, pneumatic or automatic) is used to tension the strapping looped around the goods. Tensioners come in various sizes to suit the strapping width.

5.2 Wire Buckles The buckles also come in various sizes to suit the width and breaking strength of the strapping .These buckles have either galvanized or phosphate treament finishing. The phosphated buckles (dull blackish color)are slightly moreexpensive but have better slip resistance as the phosphate treatment gives a rough finish to the surface of the buckle.

CAN POLYESTER STRAPPINGS REPLACE STEEL STRAPPINGS IN MALAYSIA?

1) BACKGROUND

In the 1980s and 1990s, steel strappings were widely used to bundle goods especially in heavy duty applications. Since then, steel strappings have largely been replaced by plastic strappings which cost less and have better performance. This trend is also largely true in Malaysia especially amongst the larger companies which use imported steel strappings. However, there are still some local companies continuing to use locally produced steel strappings due to the price aberration brought about by government policies.

2) GOVERNMENT POLICIES ON STEEL

In order to protect the local steel industry, especially of the flats segment, the government raised the import duties in March 2002 to a maximum of 50% on a total of 199 flat steel products. Companies wishing to import these products were also required to seek special import licences or approved permits(AP). The government also erected some restrictions by imposing ceiling prices for retail purchases of steel billets which are used to make steel strappings.

3)COMPARISON OF STEEL STRAPPINGS VERSUS POLYESTER CORD STRAPPINGS

| Property | Steel Strappings | Polyester strappings |

| System strength | Cannot be determined | Very high |

| Safe for users & receivers | No | Yes |

| Light weight(easily portable) | No | Yes |

| Rust or rot | Yes | No |

| Weather resistant | No | Yes |

| Shock absorbent | Minimal | Yes |

| Damage to products | Likely | No |

| High retained strength | No | Yes |

| Installation time | Slower | Faster |

4) MARKETING STRATEGY

In spite of the government policies , the woven polyester strapping is still not more expensive than the steel strapping. So, it is highly probable that the polyester strappings will eventually replace steel strappings in general use. This is no different from what is happening in the rest of the world.

5) PRICING DATA FOR STEEL STRAPPING ( APRIL 2011)

Malaysia

The retail price is about RM3200 per tonne .

5.2 USA

3/4”, 0.015 gauge, 2751 ft/coil, 110lbs/coil, price: USD160/coil

www.packagingprice.com

5.3 Australia

19mm width, 45kg/roll, price: AUD118.80

5.4 China

5.4.1 FOB Price: USD620-800/tonne

www.hualude.com

5.4.2 FOB Price: USD750 – 1188/tonne

http://bkleading.en.alibaba.com

COMPARISON OF WOVEN POLYESTER STRAPPING WITH COMPOSITE STRAPPING

1) BACKGROUND

Both type of strappings have polyester fibres as their main component. Therefore, their properties and performance are the same. Their manufacturing methods are different and so they look different physically.

The woven polyester strappings are weaved like fabric. This is one of the oldest and most reliable method of production. All lashings for extra heavy duty or safety applications are still made by weaving. The composite strapping is produced by encasing the strands of polyester cord in PE. This made the strapping stiffer and supposed to mimic the steel strapping. It was developed in the 1960s to replace the steel strapping.

2) COMPARISON

| Composite | Woven | |

| Properties i)Lightweight ii)Will not rot iii)Weather resistant iv)Shock absorbent |

Same | Same |

| Performance i)Strong as steel ii)High system strength iii)High retained tension iv)Uses retensionable buckles |

Same | Same |

| Feel | Stiff | Soft |

| Lateral strength | Low | Higher |

| Weight & Bulk | Heavier | Lighter |

| Shock absorbent | Minimal | Yes |

| Width limitation | Upto 32mm | No |

| Cost | More expensive | At least 30% cheaper |

3) Conclusion

The composite strapping was developed to challenge the steel strapping in the 1960s. A plastic strapping that feel and perform. like steel strapping was needed to change the perception of the users then. The composite strapping did a good job. By the 1990s, the steel strapping has largely been replaced by the three types of polyester cord strapping, namely, composite, glue-bonded and woven.

As a result of its history the composite strapping ranks high in the user perception. In reality, all three types of polyester cord strapping have the same performance and so are interchangeable in all applications.Any performance advantage is actually more perceived than real. However, there is a real difference in cost brought about by the different manufacturing methods.